KAJIAN PENGARUH PENGGUNAAN LUMPUR MINYAK TERHADAP KONSENTRASI TOTAL PARTIKULAT TERSUSPENSI (TSP) DAN SULFUR DIOKSIDA (SO2) DARI EMISI TANUR PUTAR INDUSTRI SEMEN (Assessment of Oil Sludge Utilization Influence on Total Suspended Particulate)

Rofie Fatimah(1*), Allen Kurniawan(2), Arief Sabdo Yuwono(3)

(1) Departemen Teknik Sipil dan Lingkungan, Institut Pertanian Bogor, Jln. Kamper, Kampus IPB Dramaga, Bogor, 16680, Indonesia

(2) Departemen Teknik Sipil dan Lingkungan, Institut Pertanian Bogor, Jln. Kamper, Kampus IPB Dramaga, Bogor, 16680, Indonesia

(3) Departemen Teknik Sipil dan Lingkungan, Institut Pertanian Bogor, Jln. Kamper, Kampus IPB Dramaga, Bogor, 16680, Indonesia

(*) Corresponding Author

Abstract

ABSTRAK

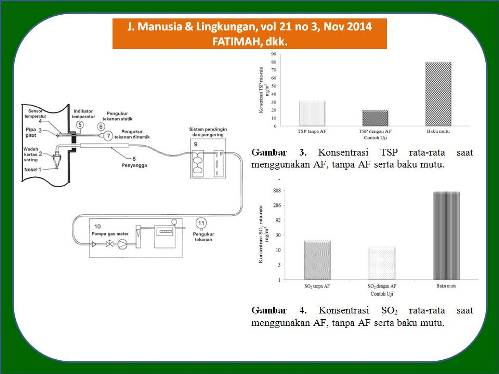

Industri semen merupakan industri padat energi dengan memanfaatkan bahan bakar fosil. Beberapa pabrik semen mencari sumber energi alternatif mengingat cadangan bahan bakar fosil terbatas dengan harga yang meningkat. Di sisi lain, pengelolaan limbah sangat dibutuhkan sebagai dampak dari aktivitas perindustrian. Co-processing merupakan salah satu upaya untuk mengatasi permasalahan tersebut dengan memanfaatkan limbah industri sebagai sumber energi baru. Salah satu limbah yang dapat dimanfaatkan adalah lumpur minyak. Atas dasar deskripsi tersebut, tujuan penelitian ini untuk membandingkan konsentrasi Total Partikulat Tersuspensi (TSP) dan sulfur dioksida (SO2) yang diemisikan dari tanur industri semen saat menggunakan bahan bakar utama (batu bara) dan batu bara yang digabung dengan lumpur minyak, membandingkan konsentrasi setiap kondisi dengan nilai baku mutu yang berlaku, serta mengkaji karakteristik lumpur minyak sebagai bahan bakar alternatif. Pengambilan contoh uji dilakukan di salah satu industri semen yang telah memanfaatkan bahan bakar alternatif dengan mengacu pada standar internasional EN 13284-1 dan ISO 7934. Konsentrasi rata-rata TSP dan SO2 saat penggunaan batu bara masing-masing diperoleh sebesar 31,48 dan 19,67 mg/Nm3, sementara saat penggunaan batu bara dan lumpur minyak masing-masing adalah 19,60 dan 12,21 mg/Nm3. Kedua konsentrasi berada di bawah ambang batas baku mutu emisi masing-masing. Dari hasil beberapa penelitian, kandungan terbesar lumpur minyak berupa senyawa-senyawa organik terutama hidrokarbon. Kandungan abu dalam lumpur minyak berkisar 1,88-18,51% dan kandungan sulfur berkisar 2,06-2,26% dari total persen berat, sehingga emisi TSP dan SO2 yang dihasilkan relatif rendah.

ABSTRACT

Cement industry needs lots of energy, which fulfilled by fossil fuel. Therefore, finding alternative energy should be encouraged. On the other side, there is a need to manage the waste as the result of industrial activities. One of the alternatives is co-processing, which is a process to recover the energy and waste for industrial production process. One of the waste that has been used is oil sludge. The purposes of this research were to compare the concentration of Total Suspended Particulate (TSP) and Sulfur dioxide (SO2) when they use coal only and coal which added by oil sludge, to compare the concentrations with the standard limit, also to characterize the oil sludge. Samples were taken at one of the cement industries that have used alternative fuel according to international standard EN 13284-1 and ISO 7934. The average concentration of TSP and SO2 which only used coal were 31.48 and 19.67 mg/Nm3 respectively, while the TSP and SO2 concentration that used coal and oil sludge were 19.6 and 12.21 mg/Nm3, respectively. The concentration of TSP and SO2were below the standard limit. The major content of oil sludge are organic compounds, especially hydrocarbon. In the oil sludge, ash content ranged between 1.88-18.51% and sulfur content ranged between 2.06-2.26% of the total weight, so the TSP and SO2 emissions may be produced in low concentration.

Keywords

Full Text:

Artikel lengkap (PDF) (Bahasa Indonesia)References

Anonim, 1989. Stationary Source Emissions-Determination of The Mass Concentration of Sulfur Dioxide-Hydrogen Peroxide/Barium Perchlorate/Thorin Method. ISO 7934.

Anonim, 1998. Stationary Source Emissions-Determination of Mass Concentration of Sulfur Dioxide-Ion Chromatography Method. ISO 11632. 1998.

Anonim, 2001. Determination of Low Range Mass Concentration of Dust Part 1: Manual Gravimetric Method. European Standard EN 13284-1.

Anonim. 2006. Sustainable Monitoring of Emissions from Combustion Plants in the Indonesian Cement Industry. Research Institute of the Cement Industry.

Anonim, 2009. Pedoman Pemanfaatan Limbah B3 dalam Kegiatan Co-processing di Industri Semen. Jakarta.

Alic, C., Manea, L. M., Vasiu, T., dan Dobrei, G. 2013. Environmental Impact Due To Use of Coal in Mintia Thermal Power Plant, Revista Minelor - Mining Revue, 19(1):2-7.

Ayotamuno, M. J., Okparanma, R. N., Nweneka, E. K., Ogaji, S. O. T., dan Probert, S. D. 2007. Bio-Remediation of A Sludge Containing Hydrocarbons, Applied Energy, 84:936-943.

Mardiana, G., dan Mahardika, R, 2010. Pemanfaatan Limbah Biomass Sebagai Bahan Bakar Alternatif dalam Kegiatan Co-Processing di Semen Gresik. Seminar Rekayasa Kimia dan Proses. Semarang, 4-5 Agustus 2010.

Mokrzycki, E., dan Uliasz-Bochen´czyk, A. 2003. Alternative Fuels for The Cement Industry, Applied Energy Elsevier, 74:95–100.

Mokrzycki, E., Uliasz-Bochen´czyk, A., dan Sarna, M. 2003. Use of Alternative Fuels in The Polish Cement Industry, Applied Energy, 74:101-111.

Schuhmacher, M., Nadal, M., dan Domingo, J. L. 2009. Environmental Monitoring of PCDD/Fs and Metals in The Vicinity of A Cement Plant After Using Sewage Sludge As A Secondary Fuel, Chemosphere, 74:1502-1508.

Shie, J. L., Lin, J., Chang, C. Y., Wu, C. H, Lee, D. J., Chang, C. F., dan Chen, Y. H. 2004. Oxidative Thermal Treatment of Oil Sludge at Low Heating Rate, Energy & Fuels, 18(5):1272-1281.

Wang, Z., Guo, Q., Liu, X., dan Cao, C. 2007. Low Temperature Pyrolysis Characteristics of Oil Sludge under Various Heating Conditions, Energy & Fuels, 21:957-962.

Xu, M., Yan, R., Zheng, C., Qiao, Y., Han, J., dan Sheng, C. 2003. Status of Trace Element Emission in a Coal Combustion Process: A Review, Fuel Processing Technol., 85:215-237.

Article Metrics

Refbacks

- There are currently no refbacks.

Copyright (c) 2017 Jurnal Manusia dan Lingkungan